The Army awarded General Dynamics Land Systems a contract for its Mobile Protected Firepower light tank in 2022. (US Army)

WASHINGTON — The gun on the Army’s new light tank design sends toxic fumes into the cabin when firing, a recent report has revealed — but the service is convinced it can find a fix, and may have one in place as early as next month.

Last year the Army awarded GDLS a $1.14 billion contract to produce prototypes of its new 38-ton Mobile Protected Firepower (MPF) “light tank” design. But the fiscal 2022 Director, Operational Test & Evaluation (DOT&E) report, released last month, found that while the GDLS’s prototype has demonstrated “satisfactory progress” towards achieving “operational effectiveness, reliability, and availability to support infantry brigade operations,” several “vulnerabilities” remain that need to be fixed before the Army makes a full-rate production decision in fiscal 2025.

“Risk to achieving operational effectiveness include: minimizing the MPF’s audible signature, improving compatibility of MPF and infantry target designators to allow sharing of target information, and improving the usability of the intercom system,” according to the DOT&E report, which adds that changes need to be made to the vehicle’s cooling system, and its “survivability performance.” But nothing will raise eyebrows like the claim that when soldiers fire the main gun, “high levels of toxic fumes” fill the vehicle.

However, the Army believes the issue can be addressed and already has a fix in mind, according to Ashley John, the public affairs director for the Program Executive Office for Ground Combat Systems.

During the rapid prototype development and testing phase, “unanticipated fumes from the spent main gun rounds built up around the crew” inside the GDLS vehicle and crew hatches were opened to bring in fresh air, John explained in an email to Breaking Defense.

“To fix the issue long-term, we are adding a purge system to clear the fumes from the crew area,” she wrote, adding that the plan is to test and validate this fix in March, before it is added into the first production vehicles.

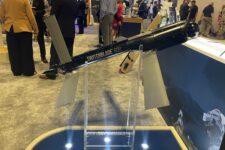

The GDLS prototype is crewed by four soldiers — a commander, a gunner, a loader, and a driver — and includes the XM35 105 mm cannon, a coaxial machine gun, and a diesel engine, according to the company and the Army.

Under the initial contract, the Army plans to buy 96 vehicles but only 26 MPFS in the first lot, Brig. Gen. Glenn Dean, program executive officer for ground combat systems, said last year. If testing goes smoothly and production stays on track, the Army should begin receiving the first production vehicles around December 2023.

Other Challenges

The DOT&E report also notes that the vehicle’s cooling system needs to be improved to reduce the number of preventive maintenance checks. John said the Army and company are working on a plan to add a more efficient heat exchanger, an improved cooling shroud, and a larger fan and supply pump to the vehicle.

As for the MPF’s sound, John said the vehicle prototype meets all of the audible signature requirements but noted that the service will continue to search for ways to make the tracked vehicle quieter.

“The DOT&E report discusses the additional noise that a tracked vehicle the size of MPF will bring to a light infantry formation. This is not a capability that those formations have traditionally had organic to their unit,” she wrote. Adding a new larger vehicle to a formation, especially one like light tank, will almost always increase the amount of noise the unit produces.

Like the report, John did not provide additional context about MPF “survivability” concerns. However, she said the Army gathered several key data points during rapid prototype testing and has a list of areas ripe for improvement during low-rate initial production (LRIP).

“The current LRIP vehicles incorporate design updates that address the classified survivability concerns referenced in the DOT&E report, which will be validated in follow-on government testing,” John wrote.

A GDLS spokesperson declined to comment on the DOT&E report, but company officials previously said they were using soldier feedback to make changes to the prototype including to vehicle cooling, the hatches and moving towards a hinged armored skirt configuration.

It is not clear at what point in time all these changes will be rolled out. However, the Army said it plans to conduct a host of MPF tests this year to include a live-fire evaluation of individual armor on the vehicle, live-fire exploitation of potential vulnerabilities, testing of the fire suppression system, and live-fire on the system as a whole using anticipated threats.

“With each live-fire test, we evaluate the vehicle’s ability to fully function after being engaged, including the critical abilities to drive, shoot and communicate,” John wrote. “We will also test design fixes to address concerns with toxic fumes build up in crew areas as well as automotive fixes with the vehicle’s ability to cool the powertrain under heat or heavy loads.”

Aloha: Fixes ongoing, then Army’s new watercraft prototype is Hawaii bound for testing

“Everything that we can knock off that list we will do in the archipelago…because that allows us to do the tests in the environment that the vessel will operate in ultimately,” said Maj. Gen. Jered Helwig.